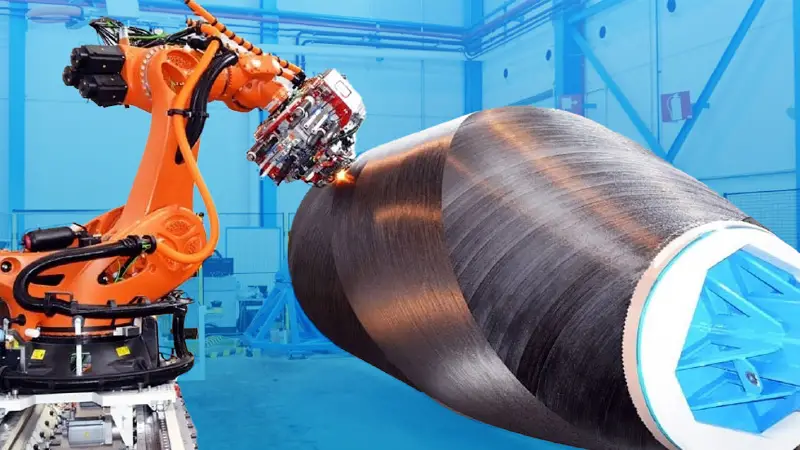

Rocket Lab has revolutionized rocket manufacturing with its groundbreaking Automated Fiber Placement (AFP) machine, designed for the Neutron rocket—the world’s largest carbon composite rocket. Weighing 90 tons, the AFP can 3D print carbon fiber layers at incredible speeds of 328 feet per minute, dramatically reducing production time and saving over 150,000 hours of labor. This advanced technology allows the AFP to lay down complex structures with unmatched precision, completing tasks that previously took teams of engineers weeks to accomplish.

Equipped with a built-in inspection system, the AFP ensures high-quality standards by automatically detecting defects in the carbon fiber composite material during the printing process. If a flaw is found, the system alerts the operator for immediate correction, maintaining the integrity of the production. With the AFP fully automating the manufacturing of large composite parts for the Neutron rocket, this innovation not only enhances efficiency but also opens up exciting new possibilities for the future of space travel through advanced 3D printing technology.

Leave a Comment